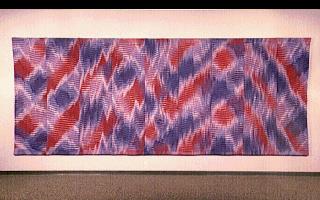

Steel Industry

Artist

Glenn Moore Shaw

Year1937

Classification

painting

Medium

oil on canvas

DimensionsVarying (see components)

Credits

Treasury Relief Art Project, 1935 - 1938

Fine Arts Collection

U.S. General Services Administration

Fine Arts Collection

U.S. General Services Administration

- The Treasury Relief Art Project commissioned this mural for the public lobby of the Canton Post Office. Since Canton is largely noted for its steel industry, Shaw believed the process of the steel industry to be an appropriate theme for the murals. Shaw remarked, "On entering a steel plant, one is conscious of the immensity of the machinery and the relative insignificance of man." He attempted, in these murals, to record his impression of the subordinates of men and glory of the machine. Beginning at the north end of the lobby, the first scene is a Hulett unloader, unloading iron ore from the hold of a lake steamer. The second scene is an exterior view of a blast furnace while tapping heat. The third scene is an interior view of a blast furnace during the process of tapping and showing the molten metal being diverted into ladle cars. The fourth scene illustrates teeming an electric furnace. Here alloys are added for varying steel characteristics. The fifth scene is the filling of ingot molds from a ladle of molten steel suspended from a traveling crane. The sixth scene is the removal of a hot ingot from the soaking pit. The seventh scene shows the breakdown mill and the first rolling for making bar steel, in which the diameter is reduced and the length extended. The eighth scene is the seamless tube mill, where hot steel bars are pierced and rolled over a mandrel to form the seamless tubing. The ninth scene shows hot sheet steel being quenched and coiled before the final rolling to gauge. The tenth scene is the steel hammer, where steel is forged into special shapes. The eleventh scene illustrates electric welding, a fabrication method that maintains the strength and physical structure of the original metal. The twelfth scene shows the pushing of coke, a by-product of the steel industry used as fuel in the charging of the blast furnace. The thirteenth scene is the quenching of hot coke under the chimney-like structure, after which it will be broken up into the exact size used by the furnace.